LAUNDRY HISTORY….

Laundry was first done in watercourses, letting the water carry away the materials which could cause stains and smells. Laundry is still done this way in some less industrialized areas and rural regions. Agitation helps remove the dirt, so the laundry is often rubbed, twisted, or slapped against flat rocks. Wooden bats or clubs could be used to help with beating the dirt out. These were often called washing beetles or bats and could be used by the waterside on a rock (a beetling-stone), on a block (battling-block), or on a board. They were once common across Europe and were also used by settlers in North America, similar techniques have also been identified in Japan.

Various chemicals may be used to increase the solvent power of water, such as the compounds in soaproot or yucca-root used by Native American tribes.soap, a compound made from lye (from wood-ash) and fat , is an ancient and very common laundry aid. However, modern washing machine typically use powdered or liquid laundry deterqent in place of more traditional soap.

When no watercourses were available, laundry was done in water-tight vats or vessels. Sometimes large metal cauldrons were filled with fresh water and heated over a fire; boiling water was even more effective than cold in removing dirt. The washboard, a corrugated slab of a hard material such as metal, replaced rocks as a surface for loosening soil.

Once clean, the clothes were wrung out — twisted to remove most of the water. Then they were hung up on poles or clotheslines to air dry, or sometimes just spread out on clean grass.

The Industrial Revolution

The industrial revolution completely transformed laundry technology.

The mangle(US) was developed in the 19th century — two long rollers in a frame and a crank to revolve them. A laundry-worker took sopping wet clothing and cranked it through the mangle, compressing the cloth and expelling the excess water. The mangle was much quicker than hand twisting. It was a variation on the box mangle used primarily for pressing and smoothing cloth.

Meanwhile 19th century inventors further mechanized the laundry process with various hand-operated washing machines Most involved turning a handle to move paddles inside a tub. Then some early 20th century machines used an electrically powered to replace tedious hand rubbing against a washboard. Many of these were simply a tub on legs, with a hand-operated mangle on top. Later the mangle too was electrically powered, then replaced by a perforated double tub, which spun out the excess water in a spin cycle.

Laundry drying was also mechanized, with clothes dryers. Dryers were also spinning

perforated tubs, but they blew heated air rather than water.

Stages of Operation

When linen is sent to be laundered, it goes through six stages. The first three stages are called "soiled side" operations, since they occur before the linen is actually washed. The last three are called "clean side" operations, since they involve the handling of clean linen.

1. Soiled Retrieval

In this step, the institution's linens are collected by laundry personnel and returned to the laundry facility. Members of the institution's housekeeping staff will place the soiled linen at a collection point, usually by dropping it down a laundry chute. Laundry workers will then collect the soiled linen, place it in carts reserved for soiled linen and transport it to the laundry facility.

Linen retrieval poses a problem, especially in health care institutions. Soiled linen can be contaminated with bloodborne and airborne pathogens. For this reason, employees who retrieve soiled linen are required to use personal protective gear and standard safety precautions. This problem is especially prevalent in hospitals. Prior to sorting, the linen must be covered to prevent the spread of airborne germs.

2. Soil Sorting

At this stage, the retrieved linen is unloaded and sorted according to item type. Different items often require different washing formulas. Also, later stages in the process require the linen to be pre-sorted, since it is handled batch by batch. Heavy or biohazardous stains such as blood and feces may require longer wash times and stronger formulas. Thus it is inadvisable to mix different items of linen in the same wash batch. Large institutions often use a production-line method for soil sorting, with several full-time employees assigned to the task.

Since soiled linen may be contaminated with biohazards or sharp objects, employees involved in the sorting process are required to use personal protective equipment and standard safety precautions.

Smaller items tend to "hide" among larger items. For this reason, some sorting goes on during the washing, processing and packaging stages.

3. Washing

This is the stage in which the laundry is actually washed. The sorted linen is weighed according to the washing machine's load limit. Large washing machines are used, usually operated by a certified washer operator. The washer operator loads and unloads the washer, decides what is to be washed according to the laundry's schedule, and monitors the chemical levels in the water. Since modern tunnel washers monitor their own chemical levels and unload linen directly into the laundry's "clean area", the operator is required only to load the linen.

Proper washing depends on five factors: Water quality, mechanical Agitation, Time, Chemical concentration and Heat. Washer operators use the acronym WATCH. These five factors work together. The purer the water and the fresher the chemicals, the cleaner the laundry will be. Mechanical action exposes the surface area of the linen to the water and chemicals, ensuring that the item is thoroughly soaked. Mechanical also tends to dislodge stains. Heat helps the chemicals to react with the stains. The longer the item is exposed to heat, chemicals and mechanical action, the cleaner it will be.

Over the past twenty years, many industrial laundries have switched from conventional washers to tunnel washers, also called continuous-batch washers. Since tunnel washers don't have to be stopped for loading and unloading of linen, they provide a more continuous flow of clean laundry. Higher-volume facilities, which may process over 15,000 pounds of linen per day, often rely heavily on tunnel washers.

4. Processing

In this stage, the clean linen is dried, ironed and folded. Some items, such as towels and blankets, are put through a dryer until they are no longer damp, then sent to mechanical folders. "Wetwork" items, such as sheets, are sent through steam-powered ironers which dry, press and fold them.

Dryers use hot air and mechanical action to evaporate the moisture and chemicals from the linen prior to folding. Heated air is forced through pores into a spinning central cylinder called the drum. As the cylinder constantly spins, the linen inside tumbles, exposing the surface area to heat which evaporates the moisture. The air temperature must be carefully controlled. If it isn't hot enough, the linen won't be thoroughly dried. If it is too hot, the linen may overdry, damaging the product and creating a fire hazard.

Ironers use heavy steam-heated rollers to dry the linen while pressing out wrinkles.

Folders use mechanical action to fold the linen into shapes that are easily stored and handled. Folders come in two varieties: large-piece for blankets and other large items, and small-piece for smaller items such as towels or pads. The more compact the shape into which the item is folded, the greater the amount of linen that can be packed into a limited storage space.

Some items, such as wash cloths, may be too small to be handled mechanically. These items must be packaged by hand.

5. Packaging

In this step, the processed linen is prepared for delivery. Individual orders are filled, based on the needs and requests of the laundry's customers, then sent to the laundry's main distribution points and storage areas. Linen not used for orders is placed in storage areas, giving the facility a reserve of clean laundry.

6. Distribution

In this step, trained delivery people transport the clean linen back to the customers. This is a skilled position, since the delivery person must have a thorough knowledge of both laundry operation and the principles of good customer service. In hospitals, delivery people must be familiar with patient relations, confidentiality policies and hospice. Large institutions will usually employ several full-time delivery people

Production Problems

Communication

Like any good business, a laundry's operation depends on good communication. Customers must file their orders in a timely manner. Delivery people and order fillers must keep records of the types and quantities of linens used. Managers must be informed of production difficulties and attitude problems. Any breakdown in communication will hinder the laundry's productivity.

Cross-contamination.

Clean linen and soiled linen should never be mixed. For this reason, most laundry facilities have two major work areas, the "soiled area" and the "clean area". These areas are usually separated by a wall. Separate carts are designated for clean and soiled linen. Linen usually passes from the soiled area to the clean area through the washers. Any clean linen that comes into contact with soiled linen or with carts used to transport soiled linen is considered soiled and must be re-washed. Laundry workers who handle soiled linen are required to wash their hands before working with clean linen.

Wet linen storage.

Wet or soiled linen that is allowed to sit for an extended period of time may become permanently wrinkled. Worse, wet linen stored in a humid area may mildew, requiring replacement.

Dust

Dust can and does settle on clean linen. For this reason, clean linen left on shelves and in delivery carts should be covered. While many laundries use dust covers specifically made for this purpose, others will improvise, using sheets or blankets.

Cart Space

Every laundry, regardless of size, has a limited amount of cart space for storing linen. For this reason, the laundry's carts must be constantly recycled. The moment a cart is emptied, it is returned to the laundry to be filled with another order. If it is designated for soiled linen, it should be emptied at the laundry facility, then sent back to the collection point for another load.

Replacement linens

Each trip through the wash cycle places wear and tear on the linen. Thus, a major laundry facility needs a constant stream of new linens coming in to replace worn-out items. Items that are not too badly damaged may be set aside for something other than their original purpose. (Permanently stained or torn blankets, for instance, may be used to line floor areas being waxed.) However, they will still need to be replaced in the linen stream.

Maintenance

From its major computerized machines down to the wheels on its carts, every laundry facility depends on mechanical and electric devices. These devices require a range of constant maintenance by skilled and certified technicians. Poorly maintained equipment can limit productivity and may even cause or contribute to injuries.

From its major computerized machines down to the wheels on its carts, every laundry facility depends on mechanical and electric devices. These devices require a range of constant maintenance by skilled and certified technicians. Poorly maintained equipment can limit productivity and may even cause or contribute to injuries.Rework

As in any business, any job that was not done properly the first time must be redone. Items that weren't thoroughly cleaned must be rewashed. Orders that were filled using the wrong supplies must be re-filled. These are two of the many examples of rework in a laundry.

Over stuffing

In recent years, it has become standard practice in prisons for prisoners to deposit personal laundry in mesh bags. The advantage of this system is that the mesh bags keep personal items separate in large loads during the wash cycle. The disadvantage is that prisoners tend to over stuff the bags. This inhibits mechanical agitation while preventing water and chemicals from reaching soiled linen. The result is poorer quality linen.

Tunnel jams

If tunnel washers have one noteworthy defect, it is the tendency for the tunnel to become blocked when the washer is overloaded. When the tunnel is blocked, the washer must be stopped and allowed to drain, then the blockage must be removed manually. A tunnel jam may cost the laundry several hours of production time. Operators can prevent tunnel jams by paying strict attention to the washer's load limits.

| |

| Coin operated laundry equipments Coin operated laundries have been here for almost fifty years now. But there is no sign of its decline. In fact, Coin operated laundries are still a very profitable business venture with great possibilities for growth. It is a business which is always in demand because every residential area requires a Laundromat service. In the laundries with coin operated equipments the main idea is self service. There are no attendants there to assist in most cases. This business if successfully managed can assure you of a steady and decent income for a long period of time with comparatively very less expenditure on your part for maintenance. Are very popular and has proven to be successful business ventures. Buying a coin operated laundromat can be a profitable but risky enterprise. Coin operated laundries equipments generally include coin operated washers, dryers, and washer-extractors. Apart from these you will require washing machines which can spin at a great speed and also machines which apply gravity to remove severe stains and dirt in fabric without damaging the cloth. If you have coin operated laundry equipments you will have to regularly do the job of emptying the machines of coins. Moreover, you will have to install a change machine there for the help of the customers. You will need to refill the change machine when they are empty. It is very much true that if you compare coin operated laundry equipments with the modern state of the art machines, the coin operated machines will appear to be outdated. But it should be kept in mind that in spite of being old fashioned the coin operated machines are less complicated and also do not possess the threat of being hacked. But before going for the coin operated laundry equipments you should decide upon the brand. While deciding about the brand does make sure that your brand is renowned and popular and the majority of the customers will accept it. This is very important for gaining the trust of the customers at the very first place. Again, you should also buy those coin operated machines that are energy efficient commercial grading machines and which bears energy star rating. This can save you from big electricity and water bills. When you have finally made up your mind in regard to the business and you need equipments to begin it you have two options in regards to the equipment. Either you can buy the equipments yourself or you also have the option of taking the equipments on lease. If you make an agreement with a company for the supply of the machines on lease the company will be liable for the maintenance issues and it can be of great help to you. The coin operated laundry equipments for a good and prolonged performance needs some regular and routine few maintenance actions like regular clear out of the dryer vents and exhaust house so that these equipments can work accurately. Regular maintenance can greatly enhance the performance of the machines. If the maintenance is done periodically these equipments generally remains in a good condition for a long time. |

Important notes

Why should I invest in the coin laundry business?

A coin-operated laundry is a smart investment, particularly in today's economy. It's an all cash, self-service, low labor, recession-proof business with a high return on investment. You have no inventory and no receivables to worry about. An attendant can add an additional profitable wash, dry and fold service. Self-service laundries have been a growth business in the 8O's and will continue in the 90's. Since women make up 65% of the work force today, their time is valuable. Their use of self-service laundries will increase. And with today's wash-n-wear clothing, you'll find more and more people turning to self-service laundries for their laundry needs.

Who should buy a coin laundry?

People from all walks of life, inducing retirees, should invest in coin laundries. It is a basic, common-sense, vital service business requiring minimal labor.

How much can I expect to earn on my investment?

Much of what your coin laundry will generate depends on how well you manage it. Some important factors in the success of a modern coin laundry are its location, the size of the store, the mix of equipment, the hours of operation, advertising and promotion. Depending on these variables, especially its size, a coin laundry can gross from $1,500 to $10,900 a week or more. The 1993 average return on investment nationally was 48% as per industry trade publications.

How much should I expect to pay for utilities?

If your machines are water and energy efficient, and designed for heavy-duty commercial use, the utilities cost will average 15-20% of your monthly gross income depending in which part of the country your laundry is located.

What is a good location?

Your coin laundry should be located in a high-traffic, densely populated, low-to-medium income area, with parking availability. Coin laundries also do well in middle-to-high income areas with single family homes because many two income families find it more convenient time and cost efficient to use the local coin laundry with its wash, dry & fold service. They do not wish to be tied up with laundry chores at home. Furthermore, in today's mode of life, many young couples do not have the desire or need to buy a washer or dryer, they use coin laundries.

Can a equipment dealer help to find and evaluate a location?

Among the many services Fabric-Care Industries provides is a free evaluation of your location, store design, and equipment recommendations. We also provide assistance in negotiating a lease.

What type of washers should I buy?

Front load professional washers, since a modern coin laundry is a professional laundry where the customer supplies his own labor and the coin meter is the cash register. The equipment you install for your customers to use is the most important factor in the success of your business. Customers must be more satisfied with the wash results they get in your laundry than with the wash they get in a laundry down the street or at home using an appliance washer. Customers appreciate being able to choose from a wide range of machine sizes to wash items like bedspreads, rugs, curtains or big family bundles. Your equipment must be dependable and easy to maintain and have a long useful life.

Fabric-Care Industries has 38 years of experience in the professional self-service laundry equipment market with an unmatched reputation for quality, reliability, water and energy efficiency. Providing washers in sizes and models for every laundering need.

A laundry business can be a simple and profitable business to start. There are many types of laundry businesses, including home-based and dry cleaning franchises. Knowing how to start a laundry business begins with choosing the right one for you.

Difficulty: Moderately Easy

Instructions

Decide what kind of laundry business you want to start.

Options range from a home-based laundry business to a dry cleaning business to a coin-operated laundromat. Factors that will influence your decision include how much money you have to invest and how involved you want to be in the work of the business.

Options range from a home-based laundry business to a dry cleaning business to a coin-operated laundromat. Factors that will influence your decision include how much money you have to invest and how involved you want to be in the work of the business.

Find a location.

If you plan to offer laundry and ironing services from home, your decision is easy. For a dry cleaning business you'll need a retail location. A laundromat will require a unique spot that can house washers, dryers, folding tables, etc.

If you plan to offer laundry and ironing services from home, your decision is easy. For a dry cleaning business you'll need a retail location. A laundromat will require a unique spot that can house washers, dryers, folding tables, etc.

Buy any necessary equipment.

This might include washers, dryers, folding tables, dry cleaning equipment, coin changer, cash registers and credit card machines.

This might include washers, dryers, folding tables, dry cleaning equipment, coin changer, cash registers and credit card machines.

Hire employees.

Dry cleaners and laundromats may require you to hire help. A home-based laundry business is something you can probably do yourself.

Dry cleaners and laundromats may require you to hire help. A home-based laundry business is something you can probably do yourself.

Market your services.

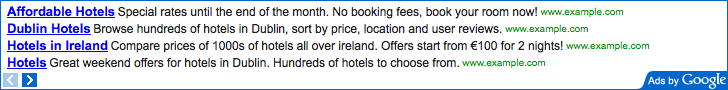

Dry cleaners often offer coupons and that will be a good way to get the word out about your laundry business. A home-based laundry business can be marketed in low cost ways, including flyers, Craigslit, and word of mouth. For a laundromat, good signage is going to be highly important in order to let people know where you are.

Dry cleaners often offer coupons and that will be a good way to get the word out about your laundry business. A home-based laundry business can be marketed in low cost ways, including flyers, Craigslit, and word of mouth. For a laundromat, good signage is going to be highly important in order to let people know where you are.

These videos will be help full...

The coin laundry business Merits and Revenue level.

There are so many businesses to choose from. Why should the Coin Laundry Business be your number one choice? See below for some reasons why the Coin Laundromat Business is a solid and attractive investment opportunity:

* Coin Laundromat Industry is mainly recession proof .

* Investment Returns can be as high as 40% .

* Little or no laundry employees needed .

* More loads, more profits a basic need in any community ,The owner can control all the cash

*Little inventory to control .

* Low manpower needed .

* Market Entry –It will make exact path and could not make much completion .

ENJOY THE ARTICLE AND MAKE COMMENT ON ...